PVDF Equal Tee

Lub npe: PVDF Equal Tee

Khoom siv: PVDF (100% nkauj xwb)

Siab siab: 0.6MPa, 1.0MPa

Jointing: Vuam, qhov (socket).

Xim: Dawb

Txuj: ISO10931

Hom: Tshiab Golden Dej Hiav Txwv

Keeb kwm: Jiangsu, Suav teb

Qhov ceev: 1.17 ~ 1.79gcm3,

Melting point: 172 ℃

Lub sijhawm ua haujlwm ntev ambient kub: -40 ~ 150 ℃

Thermal deformation kub: 112 ~ 145 ℃

Cov pa oxygen index: 46%

Crystallinity: 65% ~ 78%

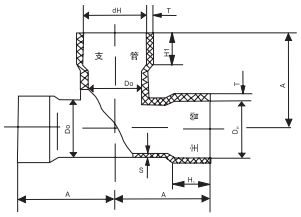

| Equal Tee | ||||||||||||

| NominalouterdiameterDe × de | Tus saib xyuas | Ceg cev | ||||||||||

| Sab nraud DiameterDo | Plhaub wallthicknessS | Qhov slot holedirectlyDH | Center rau hauv qab ntawmmouthA | Qhov armthickness T | SlotdepthH1 | Sab nraud DiameterDo | Plhaub wallthicknessS | Qhov slot holedirectlyDH | Center rau hauv qab ntawmmouthA | Qhov armthickness T | SlotdepthH1 | |

| 32 × 32 | 32 | 2.1 | 32.4 ib | 95 | 1.9 | 23 | 32 | 2.1 | 32.4 ib | 94 | 1.9 | 23 |

| 40 × 40 | 40 | 2.6 | 40.5 ib | 100 | 2.4 | 26 | 40 | 2.6 | 40.5 ib | 100 | 2.4 | 26 |

| 50 × 50 | 50 | 3.3 | 50.6 ib | 106 | 3 | 30 | 50 | 3.3 | 50.6 ib | 106 | 3 | 30 |

| 63 × 63 | 63 | 4.2 | 63.7 ib | 118 | 3.8 | 35 | 63 | 4.2 | 63.7 ib | 118 | 3.8 | 35 |

| 75 × 75 | 75 | 5 | 75.8 ua | 132 | 4.5 | 40 | 75 | 5 | 75.8 ua | 132 | 4.5 | 40 |

| 90 × 90 | 90 | 6 | 91 | 145 | 5.4 | 46 | 90 | 6 | 91 | 145 | 5.4 | 46 |

| 110 × 110 hli | 110 | 7.3 | 111.1 | 167 | 6.6 | 48 | 110 | 7.3 | 111.1 | 167 | 6.6 | 48 |

| 125 × 125 hli | 125 | 8.5 | 126.2 ib | 181 | 7.8 ib | 51 | 125 | 8.5 | 126.2 ib | 181 | 7.8 ib | 51 |

| 140 × 140 hli | 140 | 9.3 | 141.4 ib | 194 | 8.4 ib | 54 | 140 | 9.3 | 141.4 ib | 194 | 8.4 ib | 54 |

| 160 × 160 hli | 160 | 10.6 | 161.6 ib | 208 | 9.6 ib | 58 | 160 | 10.6 | 161.6 ib | 208 | 9.6 ib | 58 |

| 180 × 180 hli | 180 | 12.2 | 181.8 ib | 216 | 10.8 | 62 | 180 | 12.2 | 181.8 ib | 216 | 10.8 | 62 |

| 200 × 200 | 200 | 13.2 | 202 | 228 | 12.4 | 66 | 200 | 13.2 | 202 | 228 | 12.4 | 66 |

| 225 × 225 hli | 225 | 14.9 Nws | 227.1 ib | 236 | 13.4 | 71 | 225 | 14.9 Nws | 227.1 ib | 236 | 13.4 | 71 |

| 250 × 250 hli | 250 | 17 | 252.4 ib | 266 | 15.7 ib | 71 | 250 | 17 | 252.4 ib | 266 | 15.7 ib | 77 |

| 280 × 280 hli | 280 | 18.5 Nws | 282.6 ib | 291 ib | 16.7 ib | 82 | 280 | 18.5 Nws | 282.6 ib | 291 ib | 16.7 ib | 82 |

| 315 × 315 hli | 315 | 20.8 ib | 318 | 321 | 18.8 ib | 89 | 315 | 20.8 ib | 318 | 321 | 18.8 ib | 89 |

| 355 × 355 hli | 355 | 23.5 Nws | 358.3 ib | 375 | 21.2 | 97 | 355 | 23.5 Nws | 385.3 ib | 375 | 21.2 | 97 |

| 400 × 400 hli | 400 | 26.5 ib | 403.7 ib | 404 | 23.9 Nws | 106 | 400 | 26.5 ib | 403.7 ib | 404 | 23.9 Nws | 106 |

| 500 × 500 | 500 | 33.9 ib | 504.5 ib | 500 | 30.8 ib | 127 | 500 | 33.9 ib | 504.5 ib | 500 | 30.8 ib | 127 |

| 560 × 560 hli | 560 | 34 | 565 ib | 530 | 33.1 | 134 | 560 | 34 | 565 ib | 530 | 33.1 | 134 |

| 600 × 600 hli | 630 | 34 | 6 35 | 610 | 33.2 ib | 145 | 630 | 34 | 6 35 | 610 | 33.2 ib | 145 |

1.Efficient Fluid Transmission:

PVDF Equal Tee, kws txawj tsim los ntawm PVDF cov khoom, yog tsim los rau seamless branching kev sib txuas hauv cov kav dej, tso cai rau kev sib kis tau zoo.Nrog rau cov kav dej loj thiab ob ceg kav dej, nws ua kom cov dej ntws mus rau hauv cov lus qhia sib txawv, ua tau raws li cov kev xav tau sib txawv ntawm cov kab ke.

2. Ntau yam kev xaiv kev sib txuas:

Txhawb nqa ob lub qhov (socket fusion) thiab pob tw vuam sib txuas, Jiangyin Huada's PVDF Equal Tee muaj ntau yam hauv kev teeb tsa.Qhov no feature ua kom tus neeg siv-phooj ywg thiab yooj yim teeb tsa thiab tu txheej txheem rau cov kav dej.

3. Kev ruaj ntseg thiab kev tiv thaiv dej:

Thaum lub sijhawm ua haujlwm, PVDF Equal Tee lav kev ruaj ntseg thiab kev nyab xeeb ntawm kev sib kis ntawm cov kua dej, txo qhov kev pheej hmoo ntawm kev xau los ntawm cov yam ntxwv xws li kev hloov pauv siab thiab kub.Nws txoj kev tsim muaj zog ua kom muaj kev ruaj ntseg thiab ruaj ntseg cov dej xa khoom.

4. Ib puag ncig tus phooj ywg

Jiangyin Huada's PVDF yeeb nkab fittings yog tsim los ntawm ib puag ncig tus phooj ywg cov ntaub ntawv, uas tsis muaj teeb meem tshuaj, thiab ua raws li tej kev tiv thaiv ib puag ncig.

5. Exceptional Performance Across Environments:

Exhibiting cov yam ntxwv zoo xws li tsis kam mus rau tshuaj corrosion, kub kub, thiab oxidation, Jiangyin Huada's PVDF yeeb nkab fittings xyuas kom ntev siv nyob rau hauv ib tug kub ntawm -40 ° C mus rau 150 ° C.Qhov kev ua tau zoo tshwj xeeb no ua rau nws muaj kev xaiv txhim khu kev qha rau ntau yam tshuaj nruab nrab thiab lub cev ib puag ncig, muab kev ruaj ntseg ruaj khov thiab kev ntseeg tau ua haujlwm.

1. Chemical engineering: siv los thauj cov tshuaj corrosive xws li acids, alkalis, kuab tshuaj thiab oxidants

2. Semiconductor manufacturing: siv los thauj cov tshuaj purity siab thiab corrosive gases

3. Kev kho dej: siv hauv dej thiab kho dej khib nyiab, suav nrog kev thauj mus los ntawm cov tshuaj corrosive chemical reagents, gases thiab dej haus.

4. Mining thiab metallurgy: siv los thauj cov kua qaub thiab alkaline slurries, tshuaj reagents thiab cov kua kub kub

5. Sanitary engineering: siv los thauj cov dej purity siab, tshuaj thiab zaub mov, xws li tshuaj thiab kev ua zaub mov

6. Electroplating kev lag luam: siv los thauj cov kua qaub thiab alkaline thiab ntau yam tshuaj electroplating

Cov nqe lus them nqi: EXW, FOB, CRF, CIF

Ntim: Txheem export ntoo rooj plaub, Thawv, lossis raws li koj qhov kev thov

Pib Chaw nres nkoj: Chaw nres nkoj ntawm Shanghai lossis raws li koj qhov kev thov

Lub sij hawm xa tuaj: 15-30 hnub tom qab lees paub qhov kev txiav txim

Txoj kev thauj mus los: Hiav txwv, Railway, Huab cua, nthuav qhia, thiab lwm yam.