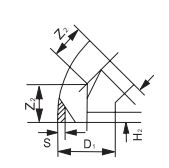

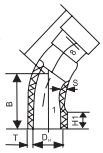

PVDF 90 Degree Luj tshib

Lub npe: PVDF 90 Degree Luj Tshib

Khoom siv: PVDF (100% nkauj xwb)

Siab siab: 0.6Mpa, 1.0Mpa

Jointing: Vuam, Socketing

Xim: Dawb

Txuj: ISO10931

Hom: Tshiab Golden Dej Hiav Txwv

Keeb kwm: Jiangsu, Suav teb

Qhov ceev: 1.17 ~ 1.79gcm3,

Melting point: 172 ℃

Lub sijhawm ua haujlwm ntev ambient kub: -40 ~ 150 ℃

Thermal deformation kub: 112 ~ 145 ℃

Cov pa oxygen index: 46%

Crystallinity: 65% ~ 78%

1.High-Tswj Kev Ua Haujlwm:

PVDF 90-Degree Luj Tshib tsim los ntawm Jiangyin Huada ua tau zoo nyob rau hauv qhov chaw kub kub, ua kom pom kev ua tau zoo txog li 150 ° C.

2.Robust Structural Integrity:

Crafted los ntawm cov khoom siv zoo tshaj plaws PVDF raw khoom, lub luj tshib no ua kom lub cev muaj zog thiab tawv tawv, muab kev tswj xyuas zoo thiab cuam tshuam rau kev ua haujlwm ruaj khov.

3.Superior Hluav taws xob rwb thaiv tsev:

Nrog tshwj xeeb hluav taws xob rwb thaiv tsev, Jiangyin Huada's PVDF 90-Degree Luj tshib yog qhov zoo tagnrho rau cov ntawv thov hauv hluav taws xob engineering thiab cov khoom siv hluav taws xob, kom ntseeg tau tias kev ua tau zoo hauv ntau qhov chaw.

4. Huab cua Resilience:

Lub luj tshib nthuav tawm cov huab cua tsis zoo, xws li tiv thaiv UV rays, ua rau nws xaiv tau ntev rau kev siv sab hauv thiab sab nraum zoov.

5.Txoj kev xaiv:

Jiangyin Huada muaj ntau yam ntawm PVDF yeeb nkab fittings, muab cov neeg siv khoom nrog kev xaiv ntau yam thiab cov lus qhia tshwj xeeb, kom ntseeg tau tias haum rau ntau yam kev xav tau ntawm cov kav dej.

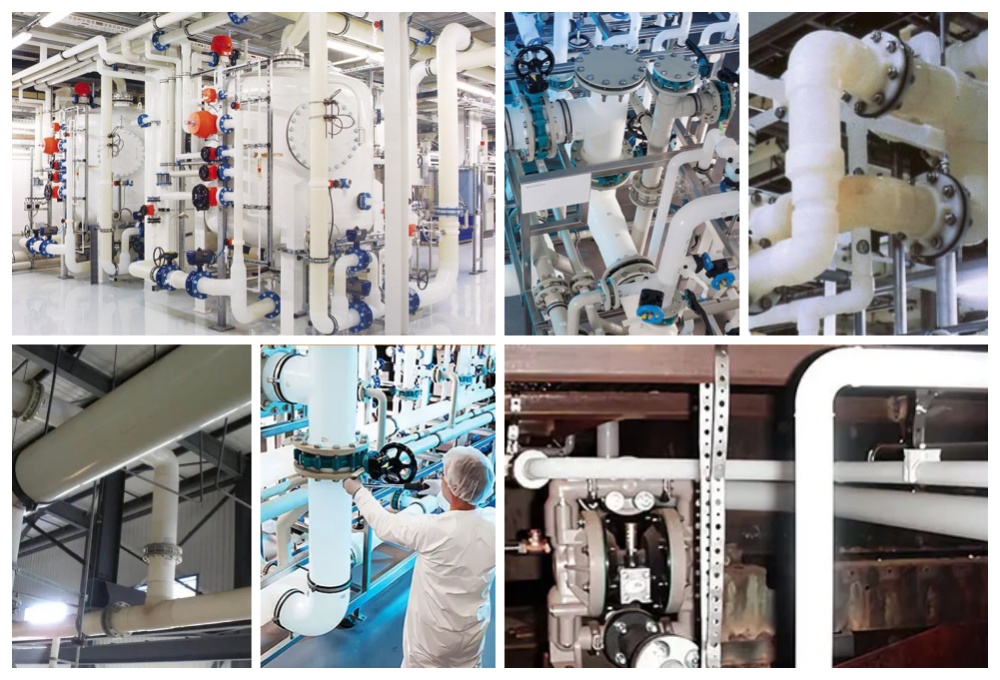

1. Chemical engineering: siv los thauj cov tshuaj corrosive xws li acids, alkalis, kuab tshuaj thiab oxidants

2. Semiconductor manufacturing: siv los thauj cov tshuaj purity siab thiab corrosive gases

3. Kev kho dej: siv hauv dej thiab kho dej khib nyiab, suav nrog kev thauj mus los ntawm cov tshuaj corrosive chemical reagents, gases thiab dej haus.

4. Mining thiab metallurgy: siv los thauj cov kua qaub thiab alkaline slurries, tshuaj reagents thiab cov kua kub kub

5. Sanitary engineering: siv los thauj cov dej purity siab, tshuaj thiab zaub mov, xws li tshuaj thiab kev ua zaub mov

6. Electroplating kev lag luam: siv los thauj cov kua qaub thiab alkaline thiab ntau yam tshuaj electroplating

Cov nqe lus them nqi: EXW, FOB, CRF, CIF

Ntim: Txheem export ntoo rooj plaub, Thawv, lossis raws li koj qhov kev thov

Pib Chaw nres nkoj: Chaw nres nkoj ntawm Shanghai lossis raws li koj qhov kev thov

Lub sij hawm xa tuaj: 15-30 hnub tom qab lees paub qhov kev txiav txim

Txoj kev thauj mus los: Hiav txwv, Railway, Huab cua, nthuav qhia, thiab lwm yam.